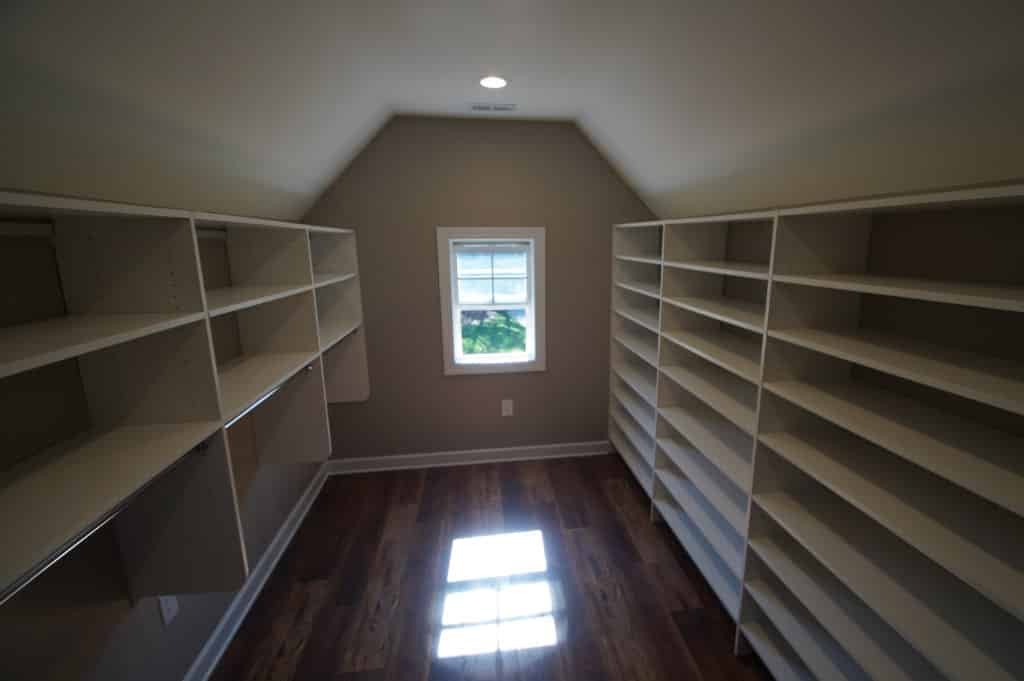

Making space for an owner’s suite closet

The owners of this house had a mainly unused and unconditioned attic space above the garage. It was so hot in the summer that candles stored there had melted all over the floor. In addition, their owner’s suite had just one small closet. They asked us to transform this space into a true owner’s suite closet.

Palmer’s Project Goals and Challenges

- The owners wanted a true master closet that provided ample storage space.

- The design of the attic trusses meant that we would have to re-engineer them.

- Hardwood floors used in other areas of the home had been discontinued.

Solutions

- We redesigned the attic roof truss system in this space to give us room to create a nice closet. We worked with an engineer to ensure that that the weight loads were supported and that everything was up to code.

- We built an 8’ wide by 12’ long walk-in closet that was well-insulated, and of course, sheetrocked and painted, creating a beautiful addition from what was untapped space.

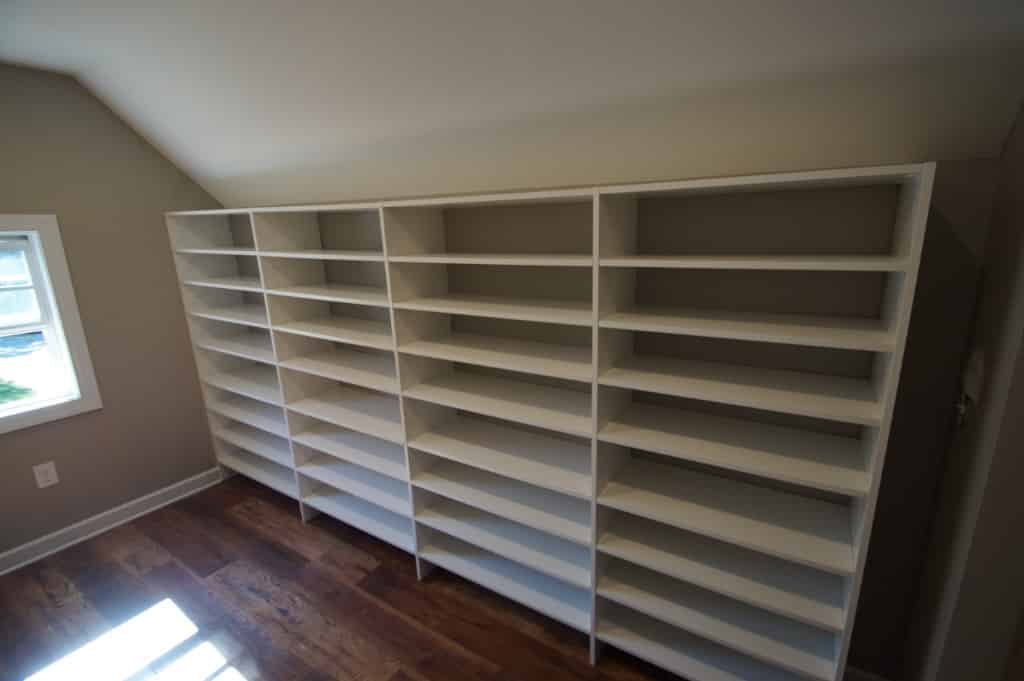

- Originally, we planned to carpet this space to match the existing small closet since the hardwood used in flooring other areas of the home had been discontinued 2 years before. Instead, we found a Luxury Vinyl Tile Plank flooring product. It is both a hard-wearing and a beautiful addition to the space. To make the suite flow, we redid the small closet with the same flooring. Recessed lights provided ample light while melamine shelving gave the owners the clothes storage space they needed.

- The original closet received other much-needed upgrades when we replaced a dated fluorescent fixture with new recessed lights and painted it to match the rest of the suite.

- As we were working in the attic space, we realized that the original sheetrock ceiling of the garage underneath wasn’t well secured. Since the owners had some very nice vehicles, we reinforced that ceiling with about 200 additional drywall screws.

- One challenge was that the existing attic window was too small to bring the framing materials and sheetrock through. Our team carefully maneuvered those materials through the house to get them into the space.

- As always, we installed protective plastic barriers as we were working to keep any construction dust out of the adjoining spaces.

- This project took 6 weeks to complete from start to finish, which included the time it took to design and special order the shelving system and the flooring.